Co-extruded Films

For over 40 years, Achilles has been a trusted partner in the medical and pharmaceutical industries, delivering customized plastic film solutions designed to meet critical healthcare needs. Our mission is clear: to support healthier living through high-performance film technology and innovation.

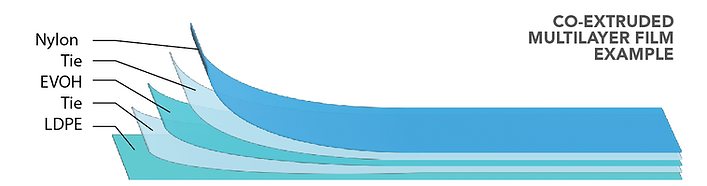

Co-extruded films combine two or more resins into a custom-engineered, multi-layer structure, designed to meet the unique demands of your application. Our coextruded capabilities provide enhanced functionality, efficiency, and consistency from pharmaceutical packaging that requires both purity and chemical resistance to industrial films needing strength and flexibility.

At Achilles, we offer 1–5 layer custom films using up to 4 different materials in a single run. Our cleanroom extrusion capabilities and automated thickness control ensure precise and reliable production, which is ideal for medical, pharmaceutical, and industrial applications.

Tailored Film Manufacturing Backed by Expertise

At the core of our operations is a cutting-edge extrusion process housed in a custom-built cleanroom. This facility allows us to manufacture films with:

-

In-line automated thickness monitoring

-

Optical camera defect inspection

-

Precision-controlled multi-layer configurations (1 to 5 layers)

-

ISO 7 Cleanroom?

-

ISCC?

A Global Partner for Contract Design & Manufacturing

Achilles works closely with clients worldwide to deliver contract manufacturing solutions that align with each project’s unique needs. Our services include:

-

Customized formulation and film design

-

Resin selection and material development

-

Test production and qualification

-

Laboratory testing capabilities, including FTIR, GC-MS, DSC, and more

Resin Selection

At Achilles USA, we offer a broad selection of high-performance resins to meet the specialized requirements of our medical, pharmaceutical, and industrial clients. Each resin brings unique properties to the film layering structure, allowing us to tailor performance attributes such as barrier protection, flexibility, clarity, chemical resistance, and sealability. By blending and layering these materials in our co-extrusion process, we design films with the precise performance characteristics required for each unique application.

-

PE (Polyethylene): A versatile, cost-effective base resin known for its flexibility, moisture resistance, and ease of processing. Often used as the sealing or outer layer in co-extruded films.

-

PP (Polypropylene): Offers clarity, stiffness, and high-temperature resistance, making it ideal for medical packaging that requires sterilization.

-

EVA (Ethylene Vinyl Acetate): Known for its softness and flexibility, EVA is often used where enhanced sealing performance or low-temperature sealing is needed. It's also chemically resistant and suitable for drug-contact applications.

-

EVOH (Ethylene Vinyl Alcohol): A premium barrier resin prized for its exceptional oxygen barrier properties and commonly used in multilayer structures where shelf-life and product protection are critical.

-

COPE (Copolyester Elastomer): Combines flexibility with strength and chemical resistance. It’s often used in demanding medical and pharmaceutical environments.

-

Nylon (Polyamide): Offers excellent puncture resistance and gas barrier properties. It’s ideal for applications requiring high mechanical strength or sterilization resistance.

-

Plastomers: Specialty polymers that balance clarity, softness, and toughness. Frequently used to enhance seal strength or modify tactile feel.

-

Elastomers: Provide stretch and resilience. Used in applications requiring impact resistance, softness, or elasticity in the film structure.